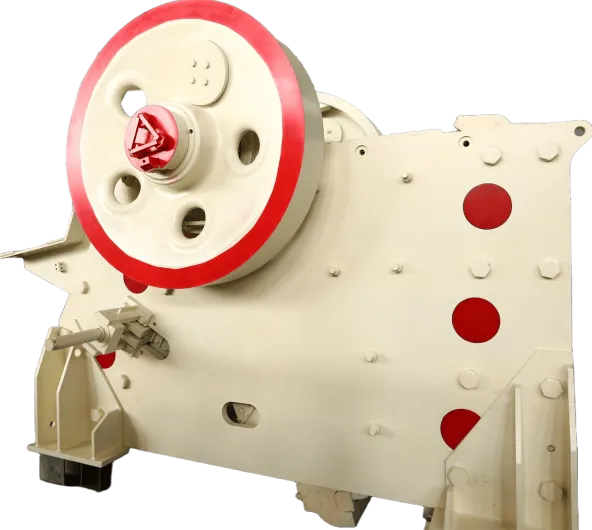

The jaw crusher is a vital piece of equipment in the mining industry, playing a key role in the initial stages of ore processing. Its primary function is to reduce large rocks, ores, and minerals into smaller, more manageable sizes for further processing. With its robust construction and high efficiency, the jaw crusher is indispensable in mining operations, ranging from surface quarries to underground excavation projects.

yude mechanical

Versatility

Can crush a wide range of materials, from soft minerals to extremely hard rocks.

High

Reduction Ratio

Converts large material into smaller, more uniform sizes.

Durability

Built to withstand harsh mining environments.

Low

Maintenance

Designed for reliability and ease of service.

Problem: Excessive Vibrations

Cause:

Misalignment of the jaw plates.

Uneven feed material or oversized rocks.

Worn-out flywheel or motor coupling.

Solution:

Regularly check and adjust the alignment of jaw plates.

Ensure uniform feed size and remove oversized materials before feeding.

Inspect and replace worn components like flywheels and motor couplings.

Problem: Reduced Crushing Capacity

Cause:

Clogged discharge area.

Worn-out jaw plates.

Incorrect feed size or material hardness.

Solution:

Clear the discharge area to prevent blockages.

Replace worn jaw plates with new ones.

Use appropriate feed material and maintain a consistent feed size.

Problem: High Energy Consumption

Cause:

Improper lubrication leading to friction.

Misaligned moving components.

Overloading the crusher.

Solution:

Regularly lubricate bearings and other moving parts.

Align and maintain all components as per manufacturer guidelines.

Avoid overloading by monitoring feed material quantity.

Problem: Abnormal Noise

Cause:

Loose components like bolts or flywheels.

Bearing damage or wear.

Collision of uncrushable materials (e.g., metal) with the crusher.

Solution:

Tighten loose components regularly.

Inspect and replace damaged bearings.

Install a metal detector or magnetic separator to prevent uncrushable materials from entering the crusher.

Problem: Uneven Product Size

Cause:

Worn or improperly fixed jaw plates.

Fluctuating feed material flow.

Solution:

Replace or refasten jaw plates securely.

Use a consistent and controlled feeding mechanism.

Problem: Premature Wear of Components

Cause:

Abrasive or hard feed material.

Poor material distribution across the jaw plates.

Solution:

Use high-quality, wear-resistant jaw plates and liners.

Distribute the material evenly across the jaw plates by adjusting the feeding system.

Problem: Crusher Jamming

Cause:

Feeding of sticky or wet materials.

Oversized material entering the crusher.

Solution:

Pre-screen sticky or wet materials to remove fines and moisture.

Use a grizzly feeder to screen out oversized rocks.

Problem: Difficulty Starting

Cause:

Motor or electrical failure.

Flywheel imbalance.

Solution:

Inspect and repair electrical connections or replace the motor.

Check and balance the flywheel as needed.

Yude

Mechanical

Create the greatest value for customers

Provide the best quality products and services

86-139-3993-0123

sales@yd-crusher.com

Luoyang Luoxin Industrial Park, Henan,China